AQUEOUS TECHNOLOGIES

For 25 years Aqueous has specialized in the manufacturing of cleaning and cleanliness testing systems for the electronics assembly industry, their equipment utilizes our planet's purest substance, water, for the removal of harmful ionic residues.

CLEANING SYSTEMS

STENCIL WASHER

CLEANLINESS TESTER

Defluxing cleaning systems, stencil washers and zero-ion testers

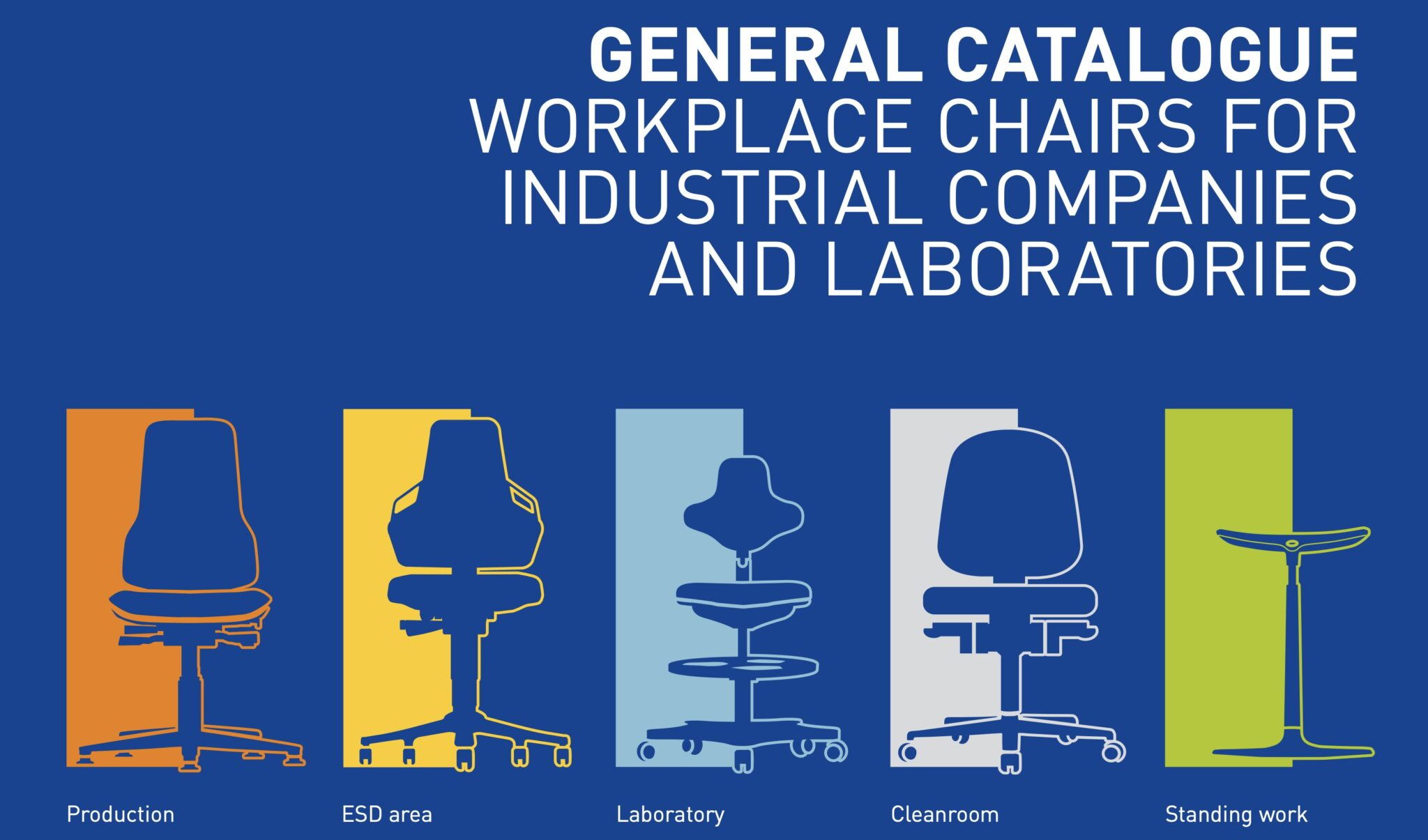

BIMOS

- Wide ranging portfolio of workplace to laboratory seating

- ESD compliant for long term work station production

- Motivate and reward employees with best-in-class function and comfort keeping them productive, healthy and happy

Production floor and laboratory seating

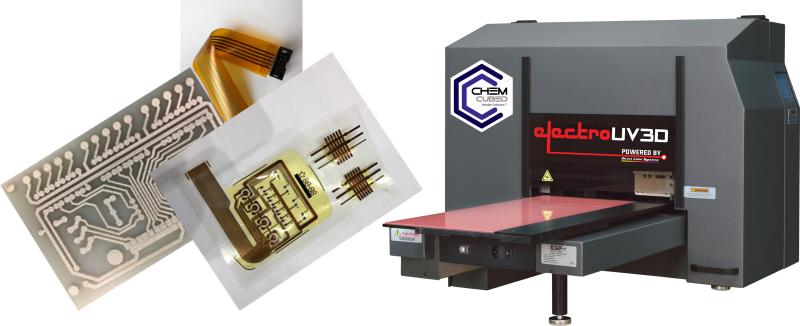

ChemCubed

ChemCubed is a U.S. based research, development and manufacturing company of nano composite material for the Additive Manufacturing (aka 3-D Printing) industry.

ChemCubed focuses on end-use applications for physical, mechanical, conductive and insulative properties for the final output requirements of UV curable and non-UV curable nano composite liquids suitable for SLA (stereolithography), syringe extrusion and piezo inkjet (jettable) technology printers.

Specialties include photopolymers and photopolymer composites for strength and durability of flexible or rigid components, as well as electrically conductive nano-particles for printed electronics circuitry. Multi-material and multi-layer capabilities enable the full integration of design and function for a true bill-of-materials reduction of parts and increased cost efficiency in manufacturing.

Key market segments are: Electronics (printed circuit boards, printed electronics), Aerospace, Automotive, Military / Defense, Medical / Optical / Dental devices and components, Security and Advanced Manufacturing.

CleancAire

Developed to destroy airborne viruses and microorganisms, especially Covid-19, Influenza & Tuberculosis.

Klearzone Technology

Air Disinfection and Purification

ECD

ECD or Electronic Controls Design Inc. is recognized worldwide for its leadership and expertise in thermal monitoring and analysis technology. Based in Milwaukie, Oregon, the company is a pioneer in the design, development, and manufacture of advanced thermal profiling systems and software used to monitor and analyze process temperatures in various industries including electronics, solar, baking, among others.

DRY STORAGE

THERMAL PROFILER

Thermal profilers & smart dry storage

EVS International

World leaders in Solder recovery, Recycle-Reduce- Reuse!

EVS International machines satisfy the high standards required from a modern manufacturing environment, particularly with regard to reliability, ease of operation, maintenance and environmental management. Lead and Lead Free Systems Available.

FKN

FKN was established in 1997 and has a broad line of depaneling equipment ranges from low cost benchtop tools such as the N100 PCB Nibbler used to singulate tab routed panels, to high volume production systems such as the K6000 In-line Multiple Circular Blade Depanelizer for singulating pre-scored boards.

CIRCULAR BLADE DEPANELIZER

PCB RACKS

PUNCH FOR TAB ROUTED PCB

ROUTED FOR TAB ROUTED PANELS

Routers and depanelizers

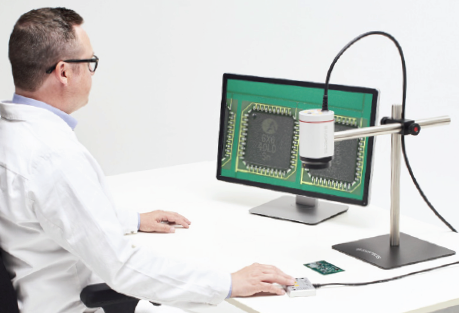

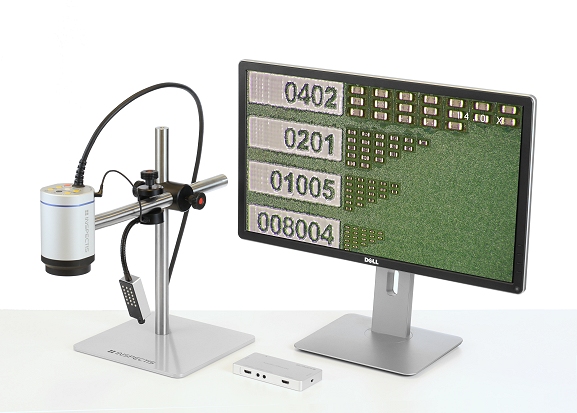

INSPECTIS

Inspectis Digital Microscopes are elegant solutions for modern optical inspection tasks. We manufacture carefully specified Optical Systems for optimum performance, sleekly designed and made from durable high quality materials making them fit for purpose of a long life in real working environments. Our cutting edge technology 4K, Full HD and USB3.0 Digital Microscopes are powerful and ready to use from the moment you plug them in. Inspectis is the leading company in 4k digital microscope technology.

Advanced Ultra HD (4K) Digital Inspection System -

- - 8.3 digital microscope

- - 30:1 optical zoom range

- - auto focus

- - XY floating board

- - Video capture with Inspectis ProX software

FULL 1080 HD INSPECTION SYSTEM WITH DIGITAL IMAGE & VIDEO CAPTURE

- Superior 30:1 zoom optics with fast auto-focus

- -Easy-to-access lens and camera controls

- -60 fps for lag-free magnified working

- -adjustable boom length and height

- -Easy image capture and video recording on USB flash

4K and HD inspection scopes

MYCRONIC

Mycronic is a Swedish high-tech company engaged in the development, manufacture and marketing of production equipment with high precision and flexibility requirements for the electronics industry. Mycronic headquarters are located in Täby, north of Stockholm and the Group has subsidiaries in China, France, Germany, Japan, Singapore, South Korea, the Netherlands, United Kingdom and the United States.

PLACEMENT

EQUIPMENT

JET PRINTER

IN-LINE DISPENSING SYSTEMS

CONFORMAL COATING SYSTEMS

SMD TOWER STORAGE SYSTEM

Placement, jet printing, storage towers, conformal coating, dispensing robots and in-line equipment

MYCRONIC VISION

As the innovative solutions provider for automated optical inspection, Mycronic serves industry leaders for PCB assembly, operating in the most demanding markets (Automotive, Aeronautics & Space, Defense, Industrial…). They provide Solder Paste Inspection (SPI), Automated Optical Inspection (AOI) systems and associated software solutions allowing their partners to set new quality standards for their manufacturing process

SPI PI SERIES

AOI K SERIES

Sigma

AOI & SPI equipment

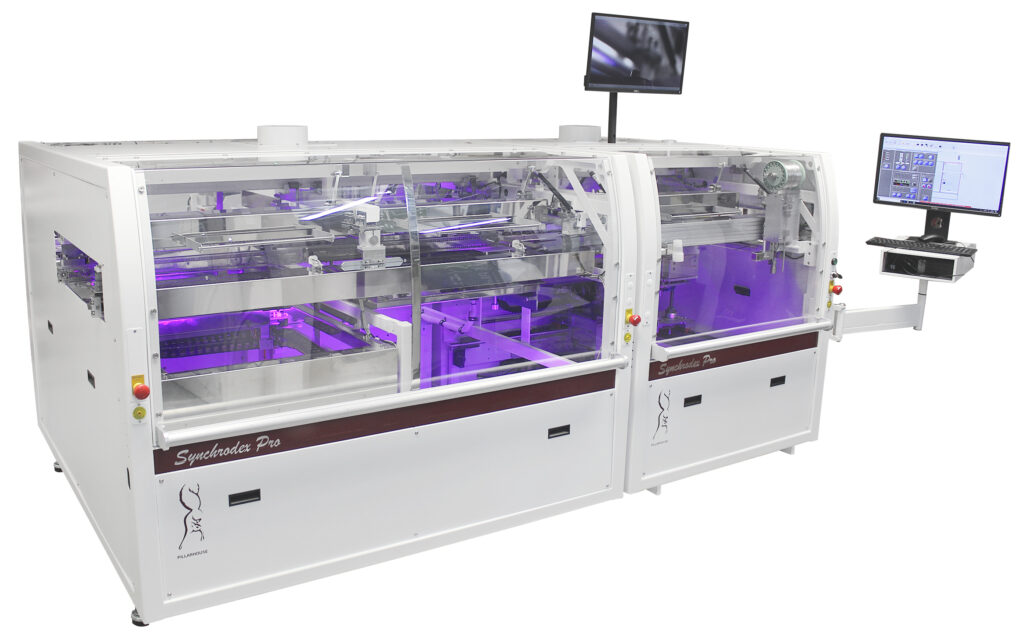

PILLARHOUSE INTERNATIONAL

Pillarhouse is the leading force in the selective soldering industry, dedicated to the ongoing development of pioneering technologies to reflect and match the needs of an ever-changing marketplace.

Offering a wide range of machine options to cover the complexity of global demand for electronics production, Pillarhouse combine engineering experience, software development and future thinking to provide cost effective and reliable selective soldering machines and equipment.

SELECTIVE SOLDERING HANDLOAD

IN LINE SELECTIVE SOLDERING

Selective soldering

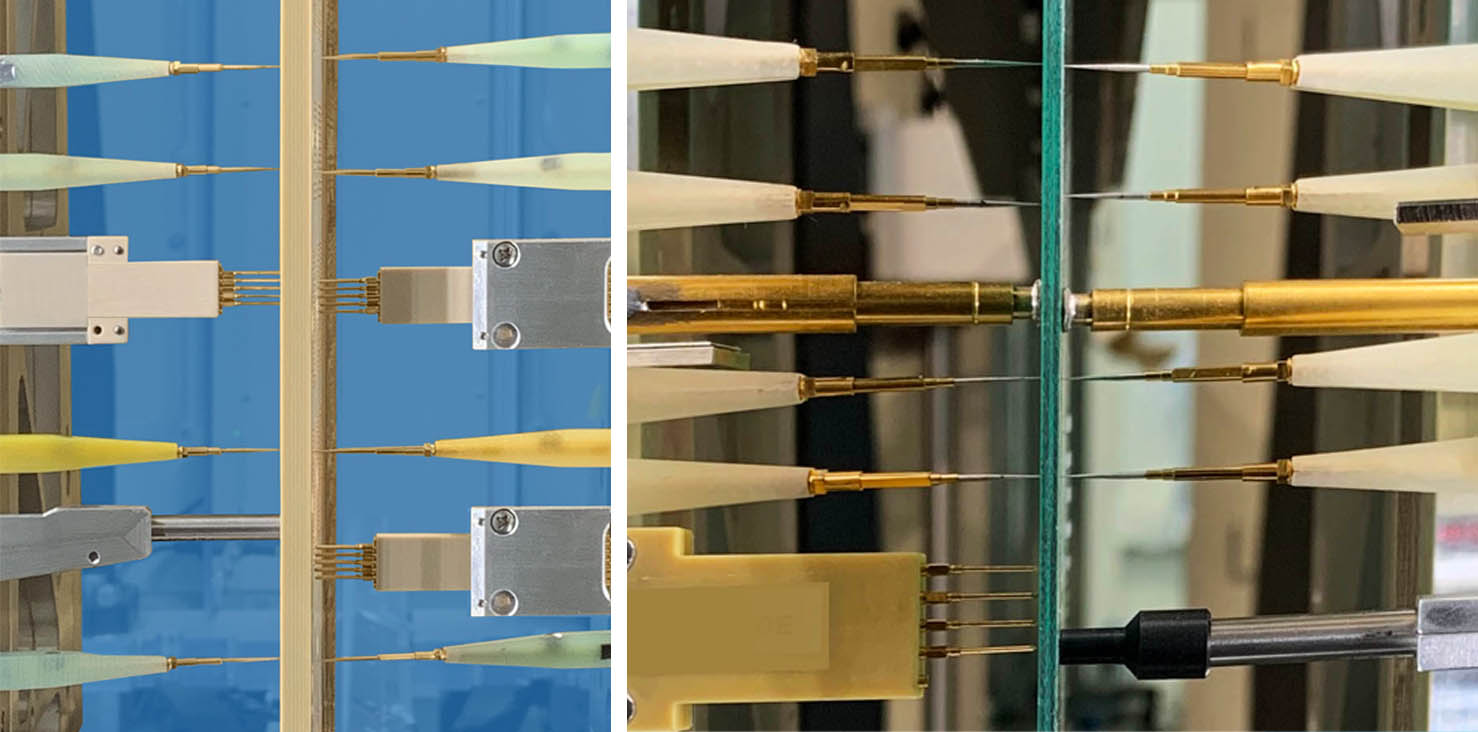

Founded in 1986, Seica S.p.A. is an innovative, high technology company that develops and manufactures leading-edge solutions for the test and selective soldering of electronic boards and modules. Combining deep expertise in electronics technology as well as in industrial machines and processes has enabled Seica to become a global leader and supplier of test and manufacturing solutions, with an installed base of thousands of systems installed on 4 different continents.

FLYING PROBE TEST

- Eliminates fixturing costs and time

- Fast test program development, easy integration of design changes

- Process flexibility

- Circuit access, even in the absence of test points

- Controlled probe contact, programmable for any type of board

- Different test solutions and approaches integrated in a single test system

- Intrinsic positioning and measurement precision

Flying Prober and Test Equipment

SurfX

After years of product development, Surfx engineers have delivered a breakthrough in argon plasma technology. Our machines provide all the advantages of vacuum plasmas, low temperature, low voltage, non-damaging, variable chemistry, and real-time process control, but with the ability to integrate the tool into assembly equipment operating at atmospheric pressure. The uniform beam of reactive gas flowing out of the plasma head is 100% electrically neutral with no streamers, no sparks, no electrostatic discharge (ESD), no ultraviolet (UV) light, and no particles. Now for the first time, plasma cleaning and activation can be safely integrated into the electronics assembly line. This breakthrough will enhance product yield, while at the same time lowering production costs.